BT Double Side

Lubricator Series Thickness 0.1~2.0 mm

Specialty

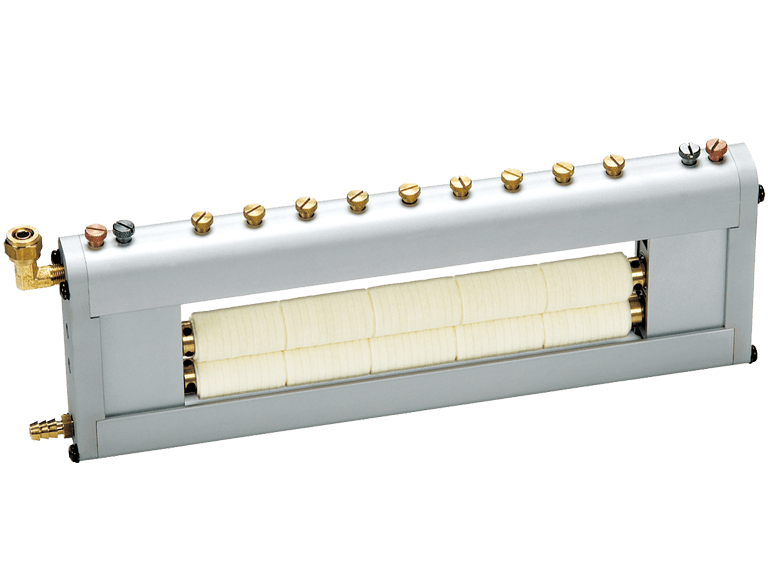

- Upperroller lubricating method :

1. Segment reinforcing oil providing is from outside of upper roller, the oil is from the yellow color copper adjusting nipples on the top rail.

2. Normal oil providing is from inside of the roller. The oil volume can be adjusted by the two red color copper adjusting nipples on both sides of the top rail. - Lower roller libricating method :

1. Normal oil providing is from inside of the roller. The oil volume can be adjusting by the two black color copper adjusting nipples on both sides of the top rail.

- The material lubricator is suitably used for material eith double sides oiling at same time to prolong greatly the service life of pressing mold.

- Aluminium alloy body structure with anodic treatment on surface, that to be beautiful and durable. A mounting bracket is included which suitable to install on all machines body.

- Special micro-adjusting oiling design, the oil volume can be controlled easily depending on the work condition. It could save oil consumption.

- This lubricator adopts high-density wool cotton material with excellent anti-wearing and powerful oil absorbing which is in separate piece model design, easily to maintenance.

- Filtering mesh is device inside the oil barrel then the lubricant can be used again.

- The option of electrical pump lubricator can combine with press for automatic & man power saving operation.

- The upper roller uses multiple nipples for different oil volume adjusting, to meet customer's special requirement.

BT Double Side + Uncoiler

Specifications

BT Double Side

| Model | Width of Material (mm) | Thickness of Material (mm) |

| BT-80 | 80 | 01.~2.0 |

| BT-100 | 100 | 01.~2.0 |

| BT-150 | 150 | 01.~2.0 |

| BT-200 | 200 | 01.~2.0 |

| BT-250 | 250 | 01.~2.0 |

| BT-300 | 300 | 01.~2.0 |

| BT-350 | 350 | 01.~2.0 |

| BT-400 | 400 | 01.~2.0 |

Micro–Adjusted Lubricator Specifications + Uncoiler

Specifications

Micro–Adjusted Lubricator Specifications

| Model | A | B | C | D | E | F | G | H | I |

| BT-80 | 198 | 113 | 42 | 80 | Ø22 | 31 | 13 | 30 | 58.5 |

| BT-100 | 218 | 113 | 42 | 100 | Ø22 | 31 | 13 | 30 | 58.5 |

| BT-150 | 268 | 113 | 42 | 150 | Ø22 | 31 | 13 | 30 | 58.5 |

| BT-200 | 318 | 113 | 42 | 200 | Ø22 | 31 | 13 | 30 | 58.5 |

| BT-250 | 368 | 113 | 42 | 250 | Ø22 | 31 | 13 | 30 | 58.5 |

| BT-300 | 418 | 113 | 42 | 300 | Ø22 | 31 | 13 | 30 | 58.5 |

| BT-350 | 468 | 113 | 42 | 350 | Ø22 | 31 | 13 | 30 | 58.5 |

| BT-400 | 518 | 113 | 42 | 400 | Ø22 | 31 | 13 | 30 | 58.5 |

Standard Accessories

Optional Accessories

- ET Lubricant thank with electromagnet valve and level switch:

The lubricant tank equipped with electromagnet valve is capable of feeding the lubricant. synchronously with the press. It lubricates when the press is in operation, and stops feeding oil when the press stops. Connected to th press control device to stop the press when the lubricant tank is out of oil. (Voltage ot electromagnet valve:110V or 220V) - SET1 Stainless lubricant tank with electromagnet valve:

The lubricant tank equipped with electromagnet valve is capable of feeding the lubricant synchronously connected to the press control system. It lubricates when the press is in operation, and stops feeding oil when the press stops. (Voltage ot electromagnet valve:110V or 220V)